6 VALID REASONS TO INVEST IN A ROBOTIC PALLETIZER

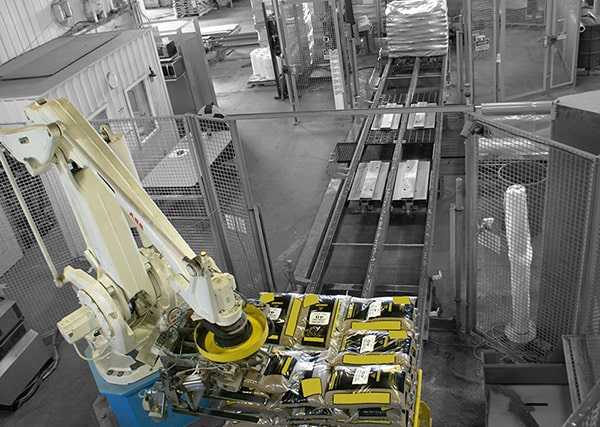

Robotic palletizers are becoming an integral part of industrial robotics. Companies handling boxes, bags, milk crates and sheet stacking onto pallets should consider equipping themselves with this type of system.

Different palletizing solutions exist, traditional and robotic solutions. In the last several years, robotic systems have taken the lead over traditional systems. This in part due to higher maintenance costs, less flexibility with traditional solutions compared to robotic and purchasing cost more expensive than a robotic solution. This article will explain the advantages of the robotic palletizing system.

TOP 6 ASSETS OF ROBOTIC PALLETIZERS

1- Improves working conditions and employee safety

The robotic palletizer is programmed to repeat continuous movements and to support heavy loads. It makes it possible to avoid work stoppages due to the strenuous physical effort that an employee needs to load a pallet.

It also eliminates problems associated with fatigue, distraction, injuries and the effects of repetitive and tedious movements.

2- Increases production flexibility

Every robotic palletizer incorporates an operator interface to organize various palletizing patterns. Robovic’s user interface flexibility makes it possible to modify, add and adjust the palletizing pattern as required. It is also possible to change products independently from production needs. This interface also allows to program in real time and independently, production changes.

The robot can also completely change its purpose either to palletize products for which the system had been designed or adapt programming or modify only certain elements of the system.

3- Maximize production speed

The repetition of movement at a constant speed and without error makes it possible to assemble a perfect pallet. In addition, some grippers are able to pick up several objects at the same time to increase the rate of production. Our robotic palletizer can reach a speed of 30 bags or 60 boxes per minute. Depending on production lines and space available, it is possible to increase the number of robots to reach higher speeds.

Gains associated to purchasing Robovic’s system are often related to lower labor costs but also linked to increased productivity.

4- Improves the quality of finished products on pallets

Repetition and precision makes the robotic palletizer possible to obtain high-quality finish for each product. The tasks performed by the robots eliminate the problems associated with fatigue, distraction and the redundancy which often lead to quality problems of finished products.

5- Restricted workspace

The robotic palletizer saves more space than conventional palletizing systems. In addition, it can be programmed to work in tight spaces and thus save precious floor space in production areas.

Robovic’s innovative angular deposit onto pallets also provides space saving for finished products. In fact, Robovic offers pallets about 10% more compact than average, thus saving storage space.

6- Reduces operating costs

These systems can operate day and night and require little or no lighting, which reduces your expenses by turning off unnecessary lighting. They are also operational at temperatures ranging from + 4C to +50 C, thus reducing your heating or cooling costs. Workforce can be regulated as supervision requires only a single person for several machines operating at the same time. In addition, Robovic’s robotic palletizers are designed to consume less energy for better energy efficiency.

Today, industrial automation presents a fundamental solution that is essential for companies to remain competitive on the market.

IF YOU WOULD LIKE TO KNOW MORE ABOUT OUR PALLETIZING SYSTEMS

Follow Us

Read more

Integrated pallet wrapper : 3 essential elements to consider for packaging products

Selecting the right industrial wrapper when integrating a palletizer is essential, discover the advantages of integrated wrapping…

What are some of the criteria to consider before installing a bagging machine ?

Discover the important elements to consider for choosing the right bagging machine.

Palletizing gripper : why control product deposit rather than letting it drop ?

Discover the advantages of depositing the products on an angle with the palletizing gripper developed by ROBOVIC…

© 2022 Robovic Inc. All rights reserved