5 KEY FACTORS TO CONSIDER BEFORE SELECTING A ROBOTIC PALLETIZING INTEGRATOR

In the era of Industry 4.0, automation is no longer seen as a simple option but has become necessary in order to make businesses more competitive. Selecting a robotic palletizing integrator always starts with the need to improve production process.

This can be achieved by increasing production capacity, reducing labor shortage, improving work and safety conditions for employees or reducing labor and operating costs.

In this article, we will highlight several important factors that make it possible to select a robotic palletizing integrator in order to obtain the most efficient solution.

#1. Reliability of the equipment and the robotic palletizing integrator

The reliability of the robotic integrator and its equipment refers not only to the durability and reliable performance of the system but also to the after-sales service and the responsiveness thereof.

With 30 years of experience, ROBOVIC has developed solid expertise in the design, manufacture and installation of palletizing solutions, bulk bag (bulk bag) and the integration of Statec Binder bagging machines. Since 1986, the company has developed more than 500 automation projects which positions Robovic as a safe bet on the market. Our experience in various sectors allows us to adapt applications to others in order to achieve the best possible combination.

#2. Technology and innovation of the robotic palletizing system

In order to select an integrator, it is important to consider advancement in terms of innovation in order to understand possible updates for the system. Robovic is continuously engaged in research and development to improve solutions and provide state-of-the-art equipment.

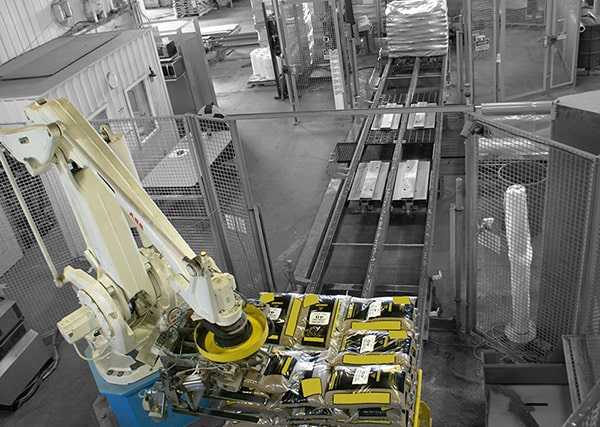

As proof, our unique angular depositing technology at Robovic is an added value to the robotic palletizer. Thanks to this solution, the system maintains control of the bag from pick up to deposit on the pallet. This manipulation and positioning technique produces a pallet that is more compact so as to optimize the quality of production.

#3. The system’s flexibility

One of the criteria not to be overlooked when choosing a robotic palletizing integrator is the technology which aims to make flexible solutions. That is to say, designing a system that can adapt to various changes of its environment, preventing loss of time or added expense.

Our palletising robots are designed to adapt to existing lines and spaces in order to increase speed or integrate new products. Indeed, our systems can adjust to production variations simply and quickly thanks to our operator interface which can manage several palletizing patterns.

#4. From design to manufacturing

Some integrators offer turnkey solutions, but do not design or manufacture the systems they install. That is why it’s important to consider a robotic integrator capable of designing and manufacturing their solutions for better flexibility in the future.

For its part, Robovic designs, manufactures and installs its systems in order to provide a complete solution to its customers. Our engineering office designs the parts internally which are then machined on our premises to be finally installed by our assemblers to provide a controlled solution.

#5. Technical support and maintenance

When selecting a robotic palletizing system, it is important that the robotic integrator offers a maintenance program in order to resolve possible problems and thus avoid production shut down.

Robovic’s main objective is to provide its customers with all the support they need. We guarantee a range of modular and tailor-made services to meet everyone’s needs. Our service includes everything necessary to optimize the performance of our systems: a reactive parts and service, maintenance and preventive maintenance formula to ensure optimal production . We also provide 24/7 technical support with a technician to solve problems day and night, by distance or directly on the spot .

No matter the size or sector, small company or large industrial group, it is important to consider all these factors when choosing a future robotic palletizing integrator in order to optimize production.

DISCOVER OUR PALLETIZING SYSTEMS

Read more

ROBOVIC will be present at ADM/PACKEX’s show in Montréal

Do not hesitate to meet us at booth #1610 to discover our end of production line solutions. The show will taking place on November 9th and 10th,2022 at the Palais des congrès in Montréal.

Integrated pallet wrapper : 3 essential elements to consider for packaging products

Selecting the right industrial wrapper when integrating a palletizer is essential, discover the advantages of integrated wrapping…

Palletizing gripper : why control product deposit rather than letting it drop ?

Discover the advantages of depositing the products on an angle with the palletizing gripper developed by ROBOVIC…